We love

sheet masks just as much as the next person. But when you throw your used mask in the trash, have you ever stopped to wonder how wasteful it actually is?

While those beloved facial products might work wonders on your skin, hydrating it and leaving it with a dewy glow, they aren’t so kind to the environment. For one thing, they generate a lot of waste ― there’s a pouch, the mask itself and sometimes a plastic sheet wrapped up in the mask ― not all of which can be easily recycled or composted, so we toss them into the garbage. That means more waste ends up in our landfills. According to the Environmental Protection Agency, containers and packaging are a huge portion of solid waste in the United States;

77.9 million tons of packaging waste was generated in 2015 alone.

Sure, your sheet masks aren’t the only things responsible for that waste, but they aren’t helping the issue, either. We spoke to some experts who broke down just how harmful those sheet masks are to the environment.

Let’s look at the materials and ingredients that go into a mask

Sheet masks are almost always meant to be single-use products. That means each time you use one, you’re generating some sort of waste.

The pouches that hold sheet masks are often made of a combination of aluminum and plastic, which according to Darby Hoover, senior resource specialist of food and agriculture at the

Natural Resources Defense Council, “cannot be recycled in typical municipal recycling systems.” It’s likely, then, that these pouches just get tossed in the trash and end up in our landfills. It’s known that plastic can take hundreds of years to decompose, if at all, and billions of pounds of plastic waste enter the world’s oceans every year, harming our wildlife, according to

National Geographic.

In Hoover’s opinion, anything that reduces the amount of packaging, makes the packaging more recyclable or uses recycled materials in production is going to help reduce the ecological footprint. Selling sheet masks in bulk ― similar to

a container of salicylic acid pads, which aren’t individually wrapped ― would also help reduce waste.

Then there are the actual masks. Sometimes they’re made from 100 percent cotton, which you might think is easily compostable, and in turn, more eco-friendly. But as Hoover points out, that’s not always the case because average consumers might not be able to decipher that some beauty ingredients in the masks could contain

sneaky plastic ingredients that make the mask impossible to compost.

Ashlee Piper, eco-lifestyle expert and author of

Give a Sh*t: Do Good. Live Better. Save the Planet, expanded on Hoover’s point, noting that a mask’s compostability is highly dependent on what’s in it. In her own research, she’s seen masks made of cotton, jute and/or bamboo, which on their own would be fine to compost. The only caveat is that if they’re soaked in non-organic, non-biodegradable ingredients, composting might not be an option.

Additionally, she said, if a sheet mask is “a synthetic material like nylon or the like, it cannot be composted and must go in the garbage.” Other non-compostable materials would include microfiber, a synthetic fabric typically made from petrochemicals.

What exactly happens when we put sheet masks in landfills?

While sheet masks aren’t going to single-handedly destroy the planet, they do generate a lot of waste, much of which likely ends up in our landfills.

As Hoover pointed out, landfills are a significant source of methane emissions and methane emissions contribute to global warming. If there are products in our landfills that contain biological or plant-based components (i.e., sheet masks), they will eventually break down and produce methane, she added, “so we want to try to not put organic products in the landfills when we can avoid it.”

That’s the tricky thing with sheet masks ― while some might contain organic or plant-based materials and ingredients, they can’t necessarily be composted, and thus they end up in landfills.

The manufacturing processes involved in producing sheet masks are also something to consider, especially if you’re trying to be a more responsible and eco-conscious consumer. In Hoover’s opinion, this aspect has a bigger ecological impact than the packaging alone.

“We’ve talked about all the ways these products likely include some type of plastic. [With] that alone, we’re taking nonrenewable fossil fuels out of the ground, turning them into plastic and creating packaging and a product that is used once and thrown away,” she said. “That is not the best use of non-renewable materials we have in our economy.”

“That upstream impact of constantly having to go back and harvest materials and all the energy, water, chemicals and other inputs that are used in manufacture are actually the greatest ecological impact,” Hoover said.

She also acknowledged that the average consumer probably doesn’t have the time or ability to figure out what each ingredient in their sheet masks is and whether it can be recycled, composted or neither. In her opinion, manufacturers and brands should provide all the information necessary for proper disposal.

“Even if some of that information is on the package and the rest of it is on a web link, that’s still really helpful to consumers who are trying to do the right thing,” she added.

What can you do if you want to be more eco-conscious?

The easiest answer, hands down, would be to avoid using non-recyclable, non-compostable, single-use sheet masks altogether. But that’s not so easy for everyone.

If you absolutely love your sheet masks and can’t give them up, just know there are other options out there that will yield similar results. As mentioned above, you can try to find products that use organic, biodegradable and recyclable materials. Korean beauty brand Innisfree has

a line of biodegradable sheet masks, for example.

Andalou Naturals, another beauty brand, also carries masks that are said to be biodegradable. The outer packaging, however, isn’t necessarily recyclable.

You can also look for masks sold in packs, as opposed to individually wrapped.

They do exist, and they don’t generate as much plastic waste as the single-use masks. Some people even

make their own sheet masks by soaking clean face cloths with their own serums or mixtures of desired ingredients, Piper said.

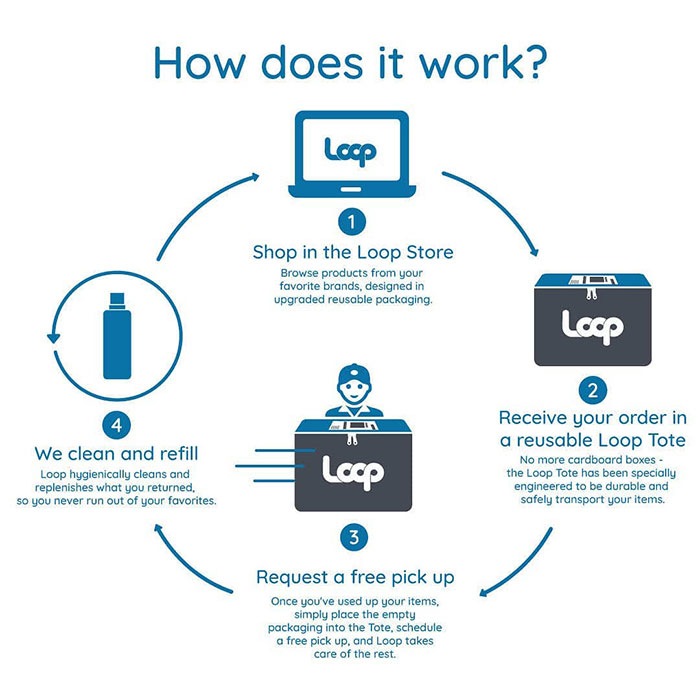

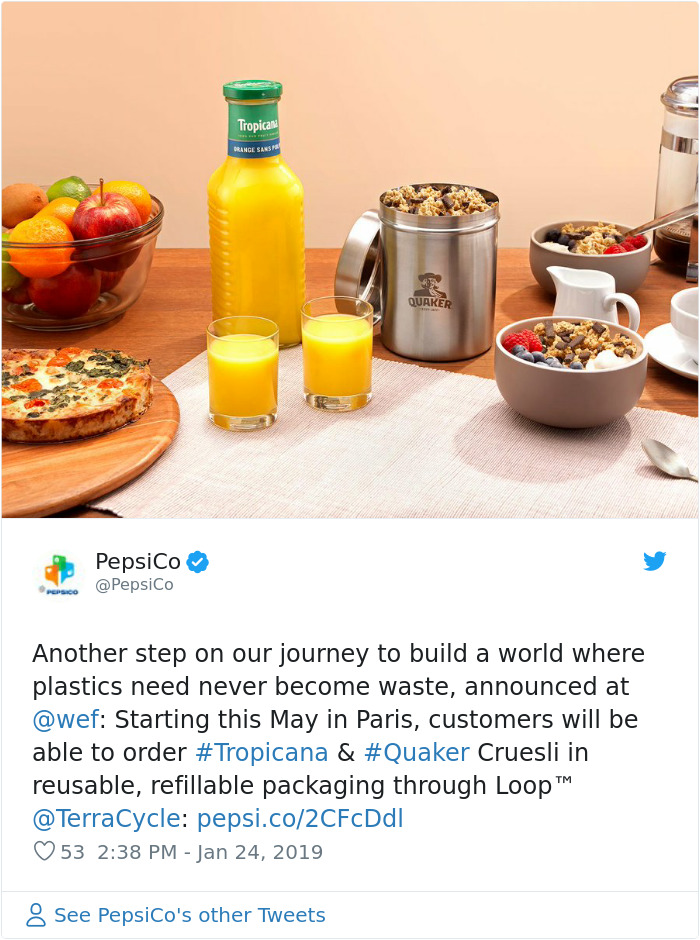

At the very least, do your research. If you really want to be more responsible, look up your local municipality’s recycling and composting guidelines. Hoover noted that every municipality in the United States has different guidelines, so it’s important to find out what they are in your area. There are also organizations like

TerraCycle that recycle typically hard-to-recycle items. You should look at your product’s packaging, as there might be some information regarding proper disposal.

“I think a big point to make is what we want from the manufacturers is [for them] to be very transparent on the packaging, about what is included, what the actual ingredients are, whether it can be recycled or composted. For both the product and package itself, there should be that kind of disclosure,” Hoover said. “It’s very important to not only get that information from the manufacturer but to match it with what your city’s guidelines are for how to responsibly recycle or compost.”